When to use NoSQL vs SQL – In this article we explain the important differences.

With the right choice of storage medium, you can build elementary more performant architectures in times of Big Data. Streaming platforms can now process huge streams of data in real time. But this technology is not a panacea. The database, for example, still occupies an important place in today’s data handling.

Often, however, it is crucial that you choose the right system for your data and in relation to the overall infrastructure.

when to use NoSQL vs SQL – Spoiled for choice

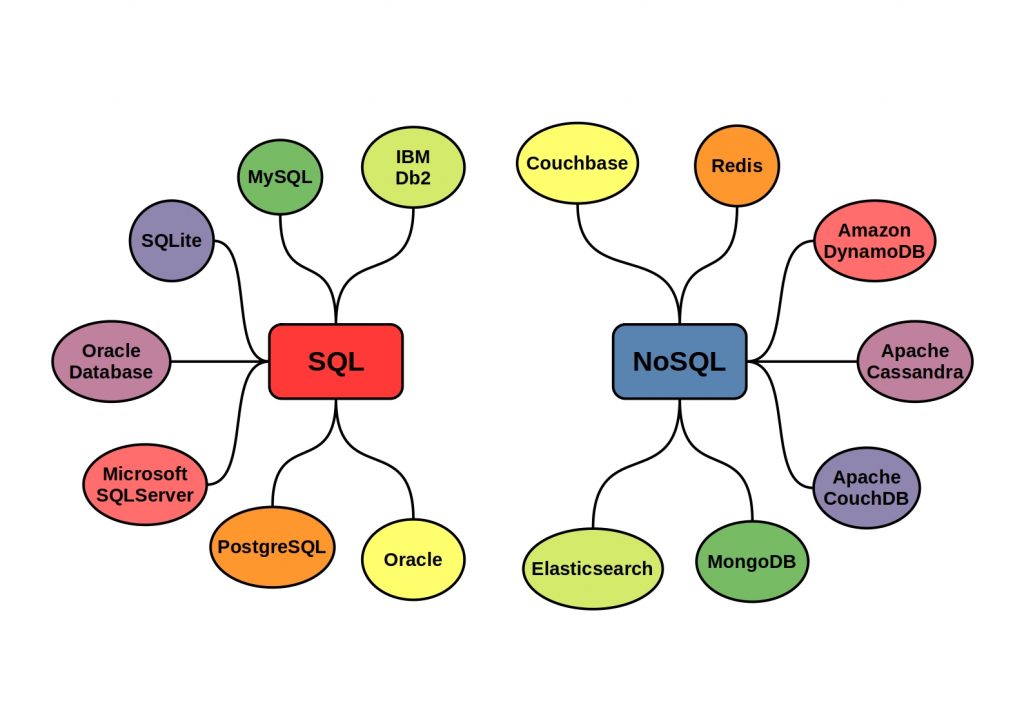

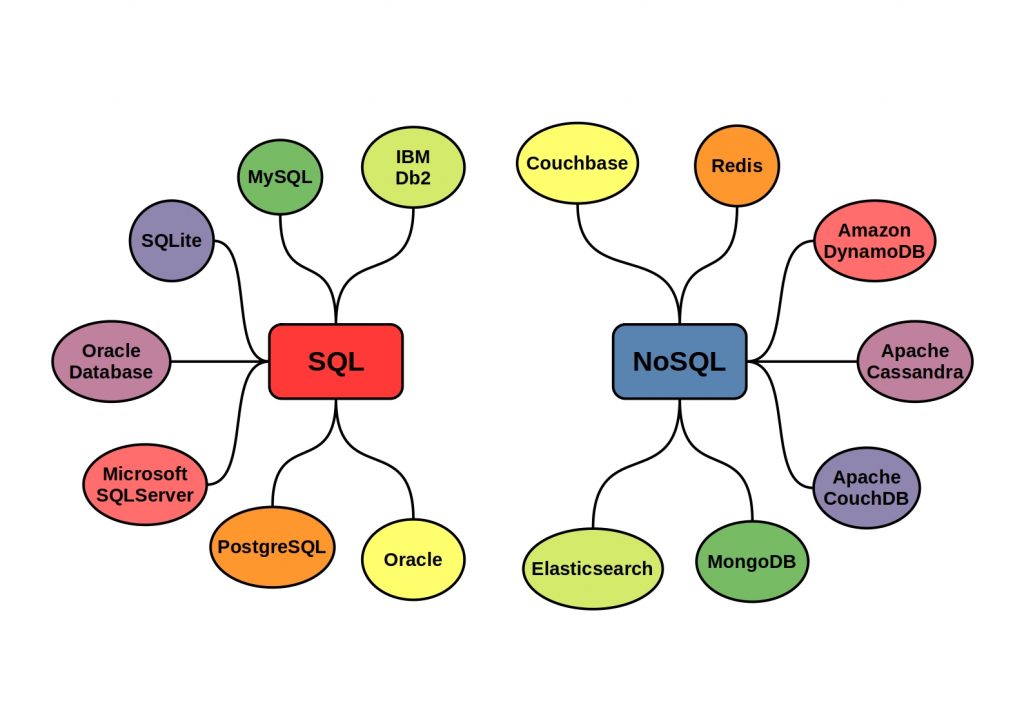

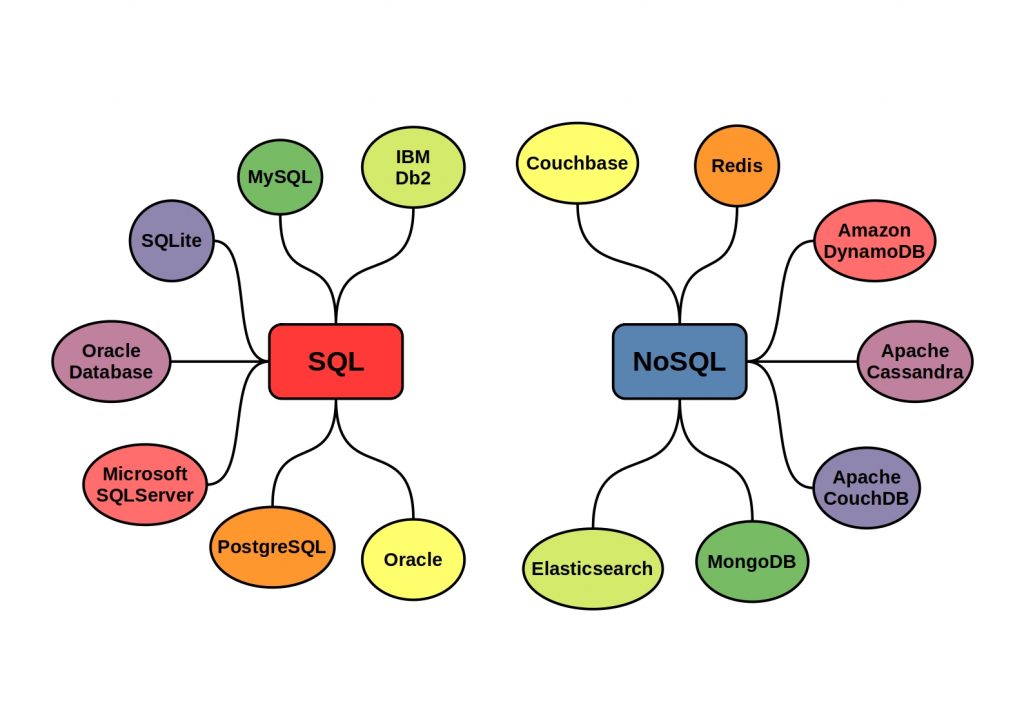

Database vendors abound. Here is just a small selection of popular databases.

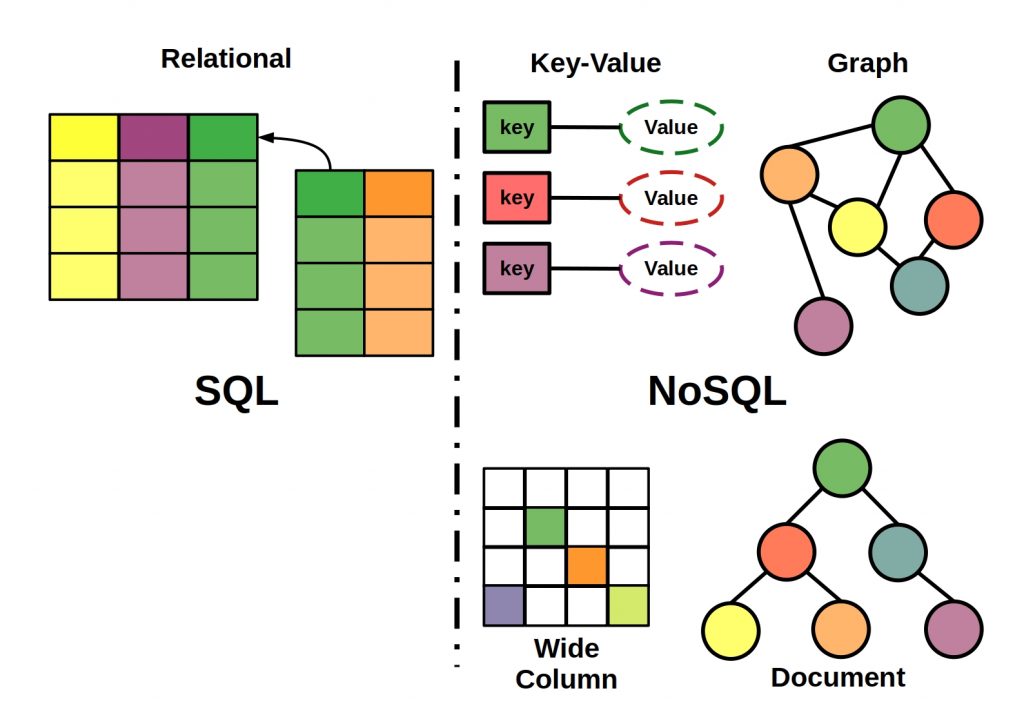

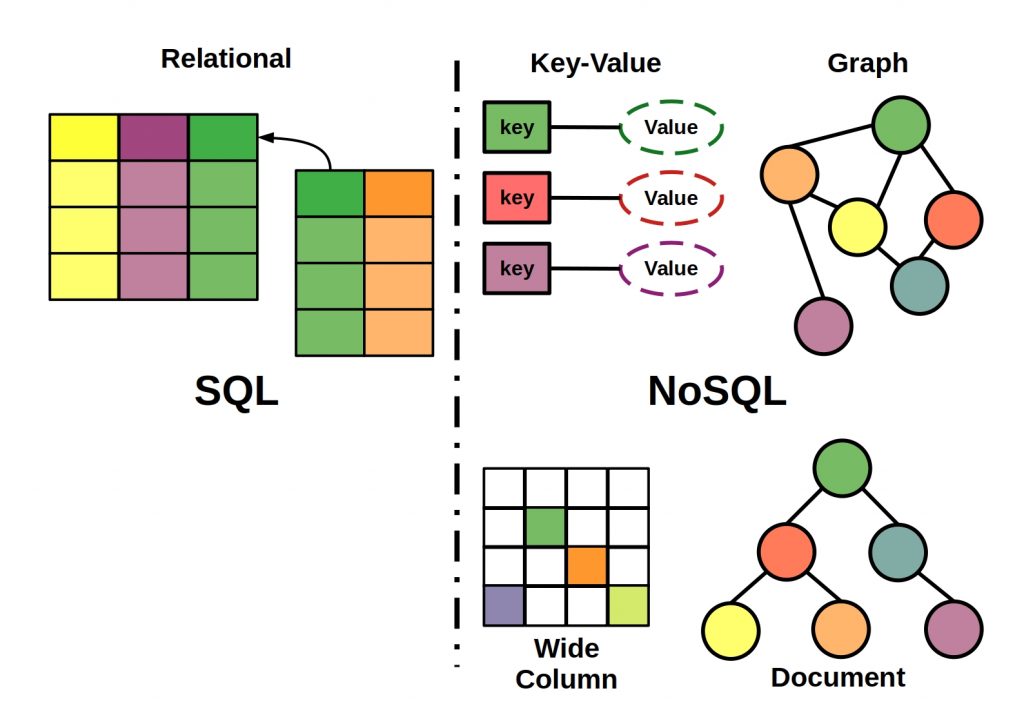

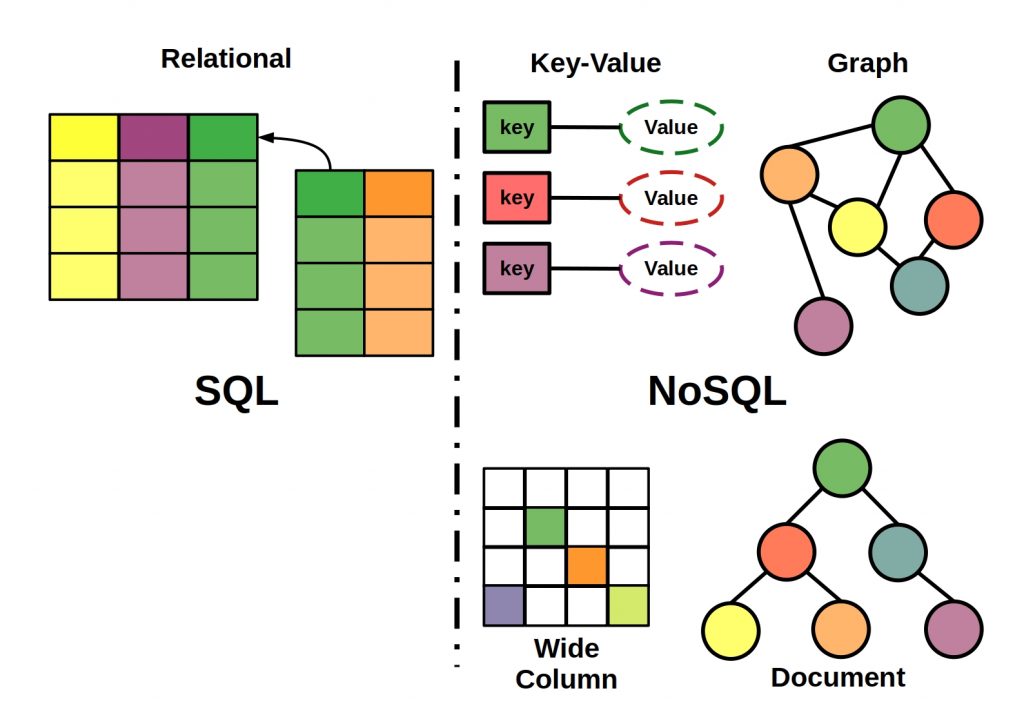

But before you get into the differences between the databases, you should basically know the differences between the systems.

SQL is relational

Structured Query Language (SQL) databases consist of a fixed defined schema structure. All schemas contain tables with columns. Each table row (tuple) represents a data set (record). In addition, each row consists of a set of attributes (characteristics).

You can use the query language to manipulate and retrieve tables. You can also control the relationships between these structured data formats. Each table in a database can be linked to each other.

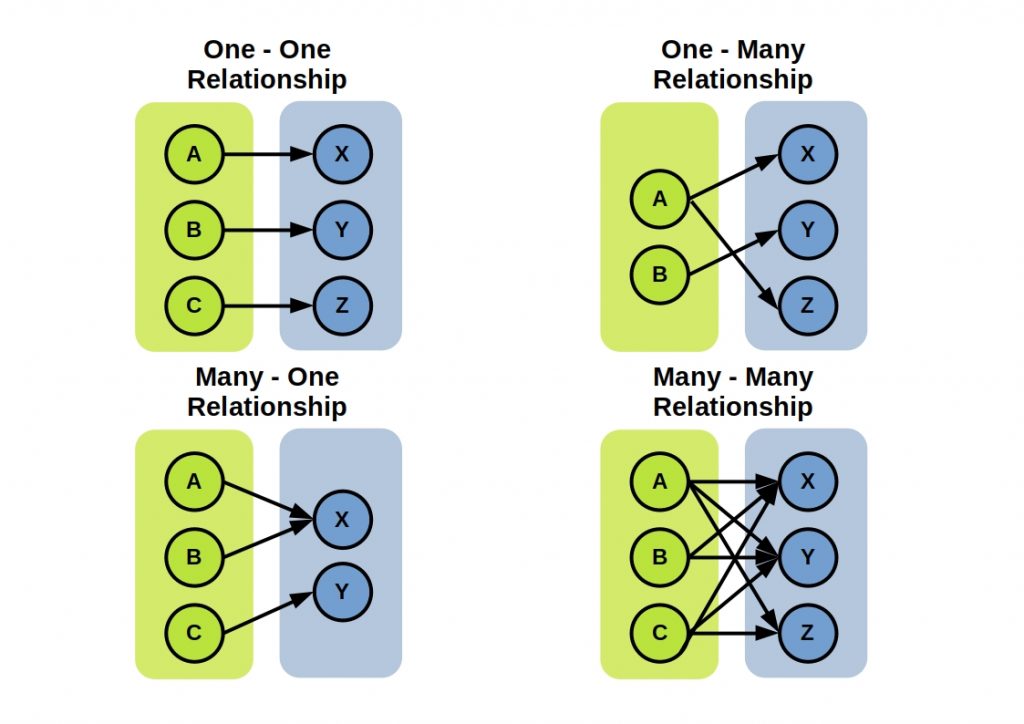

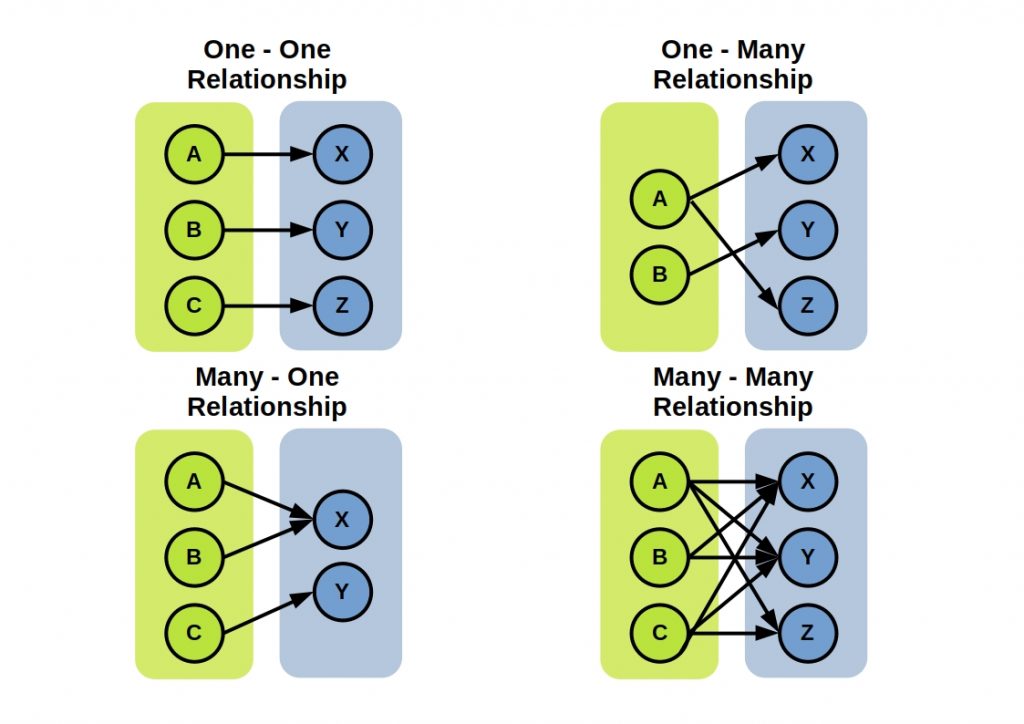

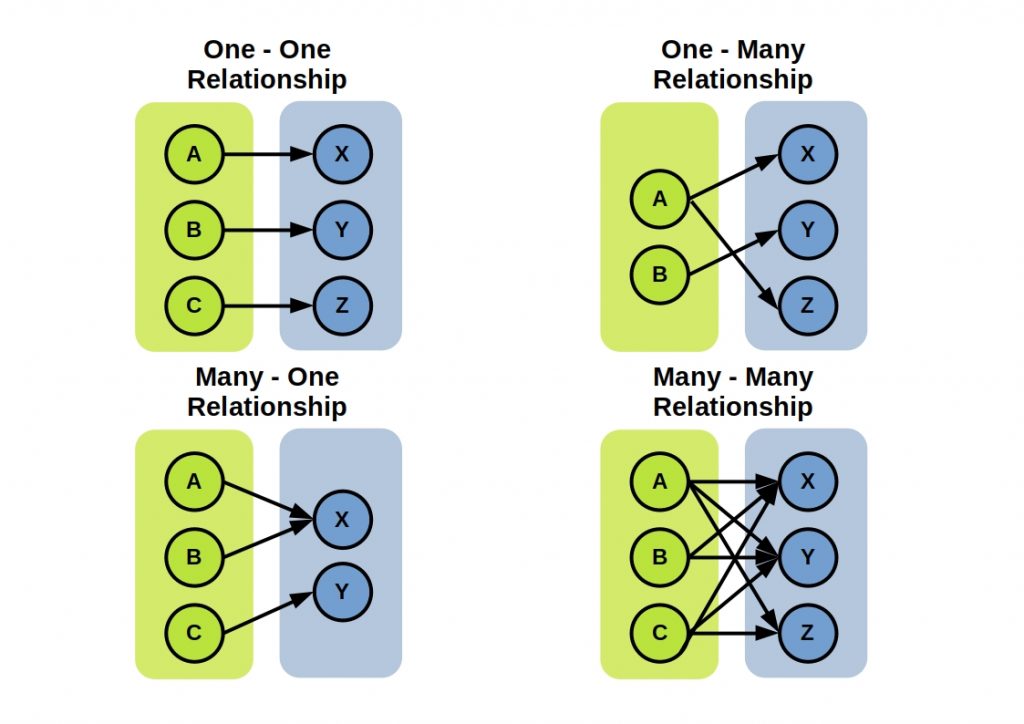

These relationships can take many forms. Table cells can have single relationships, or relationships with many cells.

NoSQL is not relational

Not only SQL (NoSQL) databases allow you to store and retrieve unstructured data using a dynamic schema. For example, your data is stored in the form of n collections, each containing m documents. Other forms are key-value stores, or graph databases. Thus, there is no special query language here

when to use NoSQL vs SQL – Both in direct comparison.

NoSQL databases exist since 1998 and is relatively young compared to SQL. SQL was already developed in the 70s. Besides the actual structure, databases of both categories differ in that they are scalable in different ways. In contrast to

NoSQL databases, SQL databases can only be scaled vertically.

Furthermore, it is important for you to know that you cannot write to and read from an SQL database in parallel. In NoSQL databases, you can read what data is available at that moment.

When to use NoSQL vs SQL

Which one suits me?

As you might have guessed, the answer here is: it depends! The differences are there and can have an important impact on the performance of your services. So the choice always depends on the application purpose. Especially for BigData use cases you should choose a NoSQL database, because here you don’t have to wait for the transaction to complete. Where you need high flexibility, due to frequently changing data structures, or real-time processing, you should also go for NoSQL DBs. However, if you want acid guarantees, you will have to go for an SQL solution. It is important for you to understand that both systems coexist, complement each other and do not replace each other.

If you want to know how to partition a database, check out this article.